Demonstration Facility

Clean Energy Systems has invested decades in testing and development to prepare our products for commercial applications.

Kimberlina Power Plant

Clean Energy Systems' Kimberlina Power Plant (KPP) is the world largest oxy-fuel combustion test facility. This former 5 MWe biomass power plant has been upgraded to support CES' testing and demonstration equipment. It is laid out primarily for R&D, sub-commercial, and commercial operations and today is home to:

- DSGG400 20 MWt Direct Steam Gas Generator

- DSGG1200 200 MWt Direct Steam Gas Generator

- 5 MWe Steam Turbine Zero Emission Power Cycle; Suitable for Continuous Operations, Capturing 1,500 Mscfd CO2

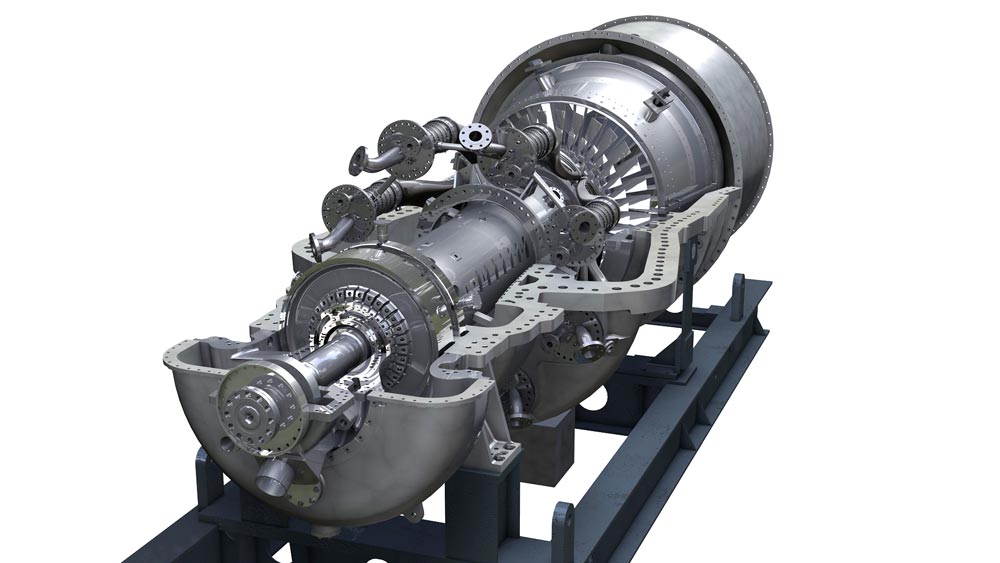

- OFT-J79 30 MWe Expander Turbine

- OFT-900 150 MWe Expander Turbine

- 28 MWt Oxy-Fuel Reheat Combustor

- Full-Scale Oxy Combustion Reheater Test Bed

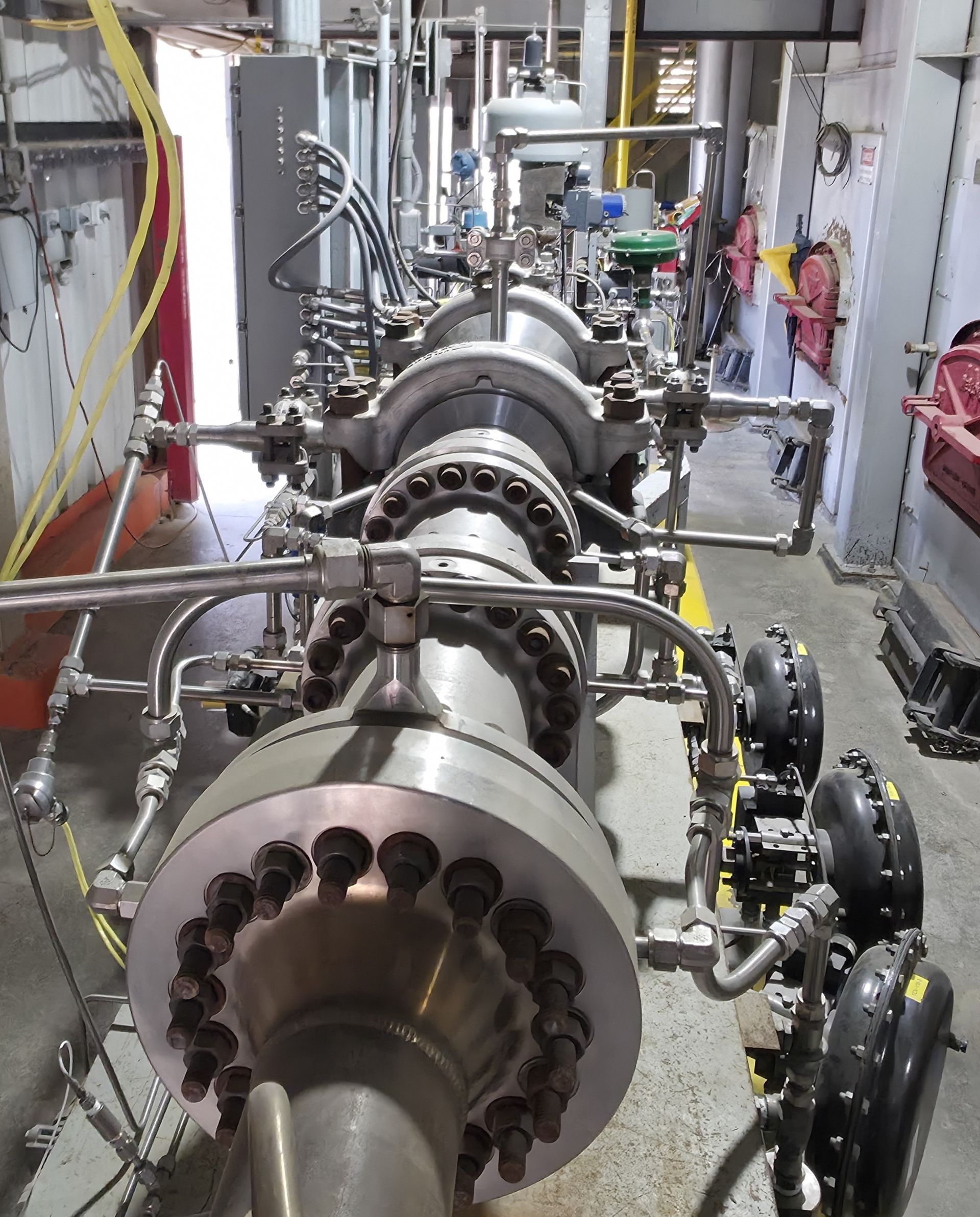

- Dedicated Heat Exchanger Test Bed

- Gas Generator and Steam Separator commercial scale test bed

What We've Achieved

- Proprietary zero emissions technology for creating large volumes of high pressure, high temperature steam-CO2 gas and clean water in a very small footprint

- Zero-emission base load power generation

- Demonstration of highly efficient and compact heat exchange technology

- Demonstration of gas reheat oxy-combustion technology

- Operation with and cleanup of field produced water

- Strong patent portfolio and with a 10 year lead over the competition

- Ability to monetize contaminated natural gas and other low quality fuels

- Demonstration of the world’s first oxy-fuel expander turbine (OFT-J79)

- Demonstration of the world's largest oxy-fuel expander turbine (OFT-900)

- Successful integration of oxy-combustor and compact heat exchange technology