Products

Direct Steam Gas Generators

Clean, Firm Power Plants

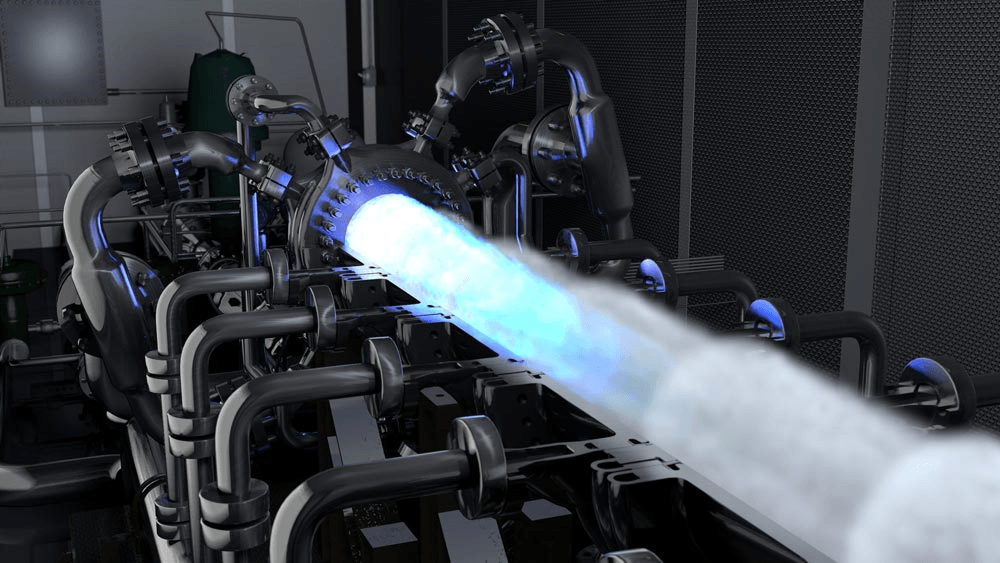

CES has developed an innovative oxy-fuel combustion system that uses natural gas and oxygen to power, steam, and/or heat for industrial processes with near zero emissions. CES’ proprietary technology is an oxy-combustion burner (“direct steam gas generator” or “DSGG”) which combusts natural gas with oxygen, in a highly efficient manner. Clean, firm power plants using CES technology produce baseload electricity and a high-purity CO2 stream, which is ready for downhole sequestration or beneficial re-use in other industrial applications. Waste heat can also be captured for use by a co-located industrial user, meaning that the clean, firm plants could operate as co-generation facilities. CES technology is highly advantaged compared to post-combustion carbon capture, as it is both lower cost and can capture almost 100% of the CO2 emissions.

CES technology is both compact, modular and scalable. Oxy-combustion burner units are packaged in transportable containers, minimizing the required on-site installation time. CES can support 20-300+ MW projects, using existing proven technology.

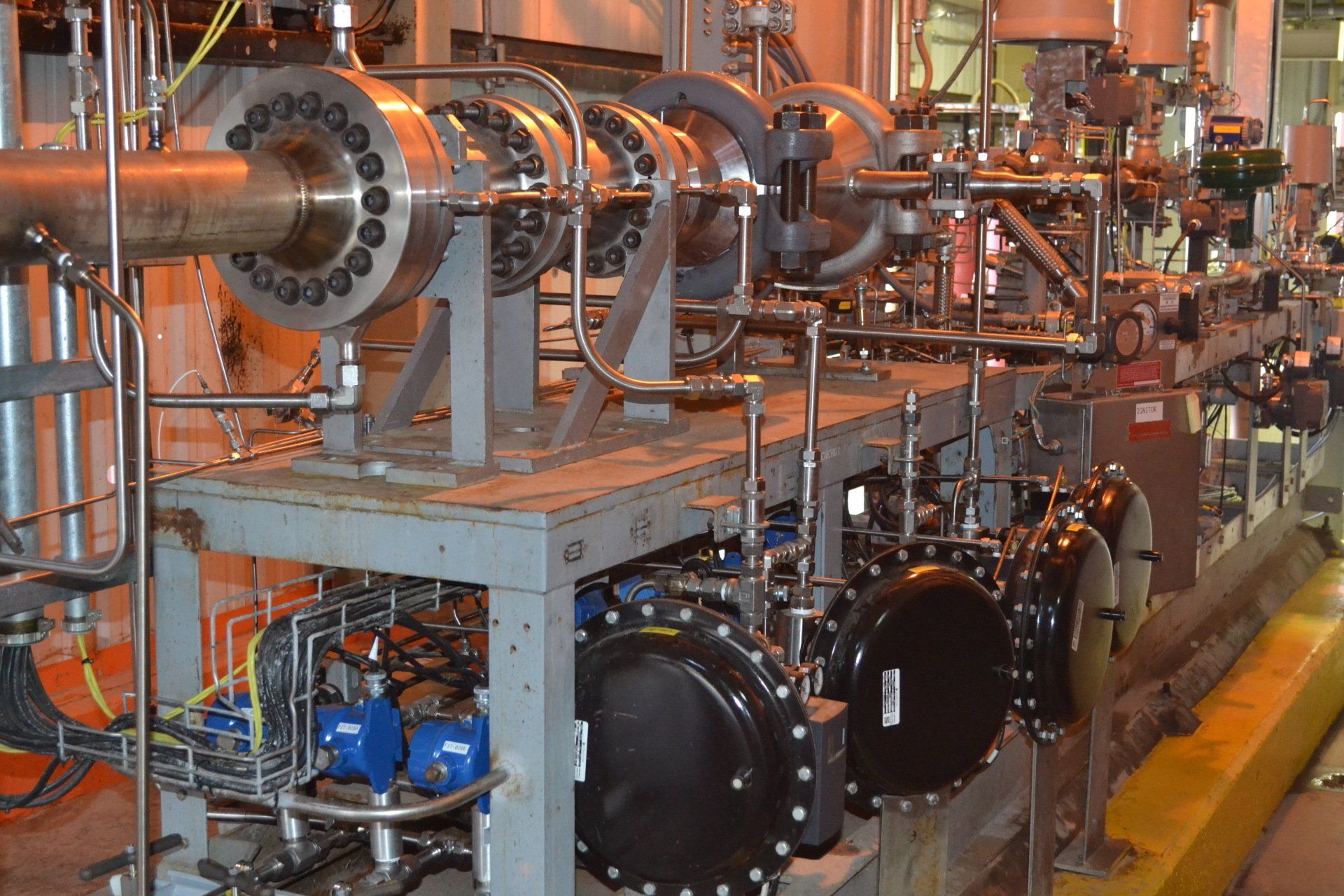

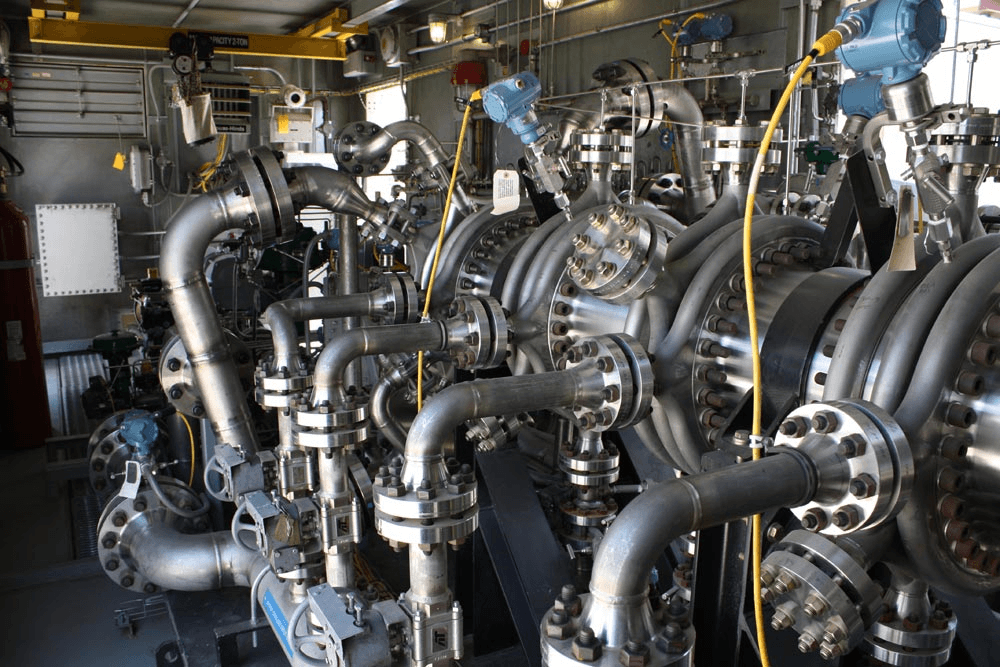

CES’ DSGG consist of three main parts: a burner, attemperator, and associated feed and controls systems. DSGG burners utilize platelet technology to intimately mix gaseous fuel with oxygen in the presence of water for stable, efficient combustion. Multiple attemperation chambers inject water to cool the resulting superheated, high-pressure steam and CO2, producing additional steam and controlling combustion. Associated water, oxidizer, and fuel feeder systems are designed for the specific fuel qualities targeted in your project. Oxygen is supplied by a traditional air separation unit (ASU).

You can learn more about CES' direct steam generation technology and some typical process configurations by downloading our brochure.

You can learn more about CES' direct steam generation technology and some typical process configurations by downloading our brochure.

Direct Steam Gas Generator 400

The DSGG400 uses a 4-inch (10 cm) internal diameter system design and is rated for 20 MWt when running on pipeline quality natural gas at typical pressures.

Applications

- Clean Firm Power

- Combined Heat and Power (CHP)

- Industrial Decarbonization

- Clean Steam Production

- Produced Water Treatment & Thermal Enhancement

- Enhanced Oil and Gas Recovery (EOR, EGR)

Typical Dimensions:

L40-45' x W11' x H11' (12-14m x 4m x 4m) in operational enclosure.

Features

- Fully containerized or skid mounted solutions for minimal install time and cost

- Fully automated control system via Allen Bradley PLC, e.g. fuel demand, temperature control, load following, etc.

- Independent control over produced gas pressure and temperature

- Easy access maintenance system for full module or component replacement

- Unit can be completely overhauled in <24 hours

- Built to ASME BPVC Section VIII Division 2

- Increased safety via high-speed ignition detection (on the order of <500ms) and minimal stored volume; unit can be tripped, purged, and made safe for internal work in <15 min.

| Power Output | 68 MM btu/hr (20 MWt) |

|---|---|

| C02 Output | up to 1,850 mscfd (~100 tonnes per day) based natural gas fuel |

| Drive Gas Output | up to 50,000 lbs/hr (22,680 kg/hr) |

| Exhaust Temp. | saturation up to 3,200 °F (1,760 °C) |

| Inlet Pressure | up to 1,500 psi (103 bar) customizable up to 5,000 psi (345 bar) |

| Pressure Drop | 10-20% |

| Operating Range | 30-100% (based on fuel flow) |

| Power Output | 68 MM btu/ hr (20 MWt) |

|---|---|

| Drive Gas Output | Up to 310,000 lbs/hr (140,610 kg/hr) |

| CO2 Output | 1,850 mscfd (~100 tonnes per day) based natural gas fuel |

| Drive Gas Composition | ~94 mol% H2O, 6 mol% CO2 |

| Exhaust Temperature | Saturation up to 3,200 °F (1,760 °C) |

| Exhaust Pressure | 1,500 psi (~100 bar); customizable up to 4,200 psi (290 bar) |

| Pressure Drop | 10-20% |

| Operating Range | 30-100% (based on fuel flow) |

| Power Output | 200 MWt |

|---|---|

| CO2 Output | up to 18,500 mscfd (~1,000 tonnes per day) based natural gas fuel |

| Drive Gas Output | up to 500,000 lbs/hr (226,800 kg/hr) |

| Exhaust Temp. | saturation up to 3,200 °F (1,760 °C) |

| Inlet Pressure | up to 900 psi (60 bar); customizable up to 5,000 psi (345 bar) |

| Pressure Drop | 10-20% |

| Operating Range | 35-100% (based on fuel flow) |

| Power Output | 682 MM btu/hr (200 MWt) |

|---|---|

| Drive Gas Output | Up to 1,600,000 lbs/hr (725,750 kg/hr) |

| CO2 Output | 18,500 mscfd (~1,000 tonnes per day) based natural gas fuel |

| Drive Gas Composition | ~94 mol% H2O, 6 mol% CO2 |

| Exhaust Temperature | Saturation up to 3,200 °F (1,760 °C) |

| Exhaust Pressure | 500 psi (34.5 bar); customizable up to 1,520 psi (105 bar) |

| Pressure Drop | 10-20% |

| Operating Range | 35-100% (based on fuel flow) |

Direct Steam Gas Generator 1200

The DSGG1200 is a scaled version of the DSGG400 using a 12-inch (30 cm) internal diameter system rated for 200 MWt when running on pipeline quality natural gas at typical pressures.

Applications

- Clean Firm Power

- Combined Heat and Power (CHP)

- Industrial Decarbonization

- Clean Steam Production

- Produced Water Treatment & Thermal Enhancement

- Enhanced Oil and Gas Recovery (EOR, EGR)

Typical Dimensions:

L40-45' x W11' x H11' (12-14m x 4m x 4m) in operational enclosure.

Features

- Fully containerized or skid mounted solutions for minimal install time and cost

- Fully automated control system via Allen Bradley PLC, e.g. fuel demand, temperature control, load following, etc.

- Independent control over produced gas pressure and temperature

- Easy access maintenance system for full module or component replacement

- Unit can be completely overhauled in <24 hours

- Built to ASME BPVC Section VIII Division 2

- Increased safety via high-speed ignition detection (on the order of <500ms) and minimal stored volume; unit can be tripped, purged, and made safe for internal work in <15 min.