Clean, Firm Power

Our Technology

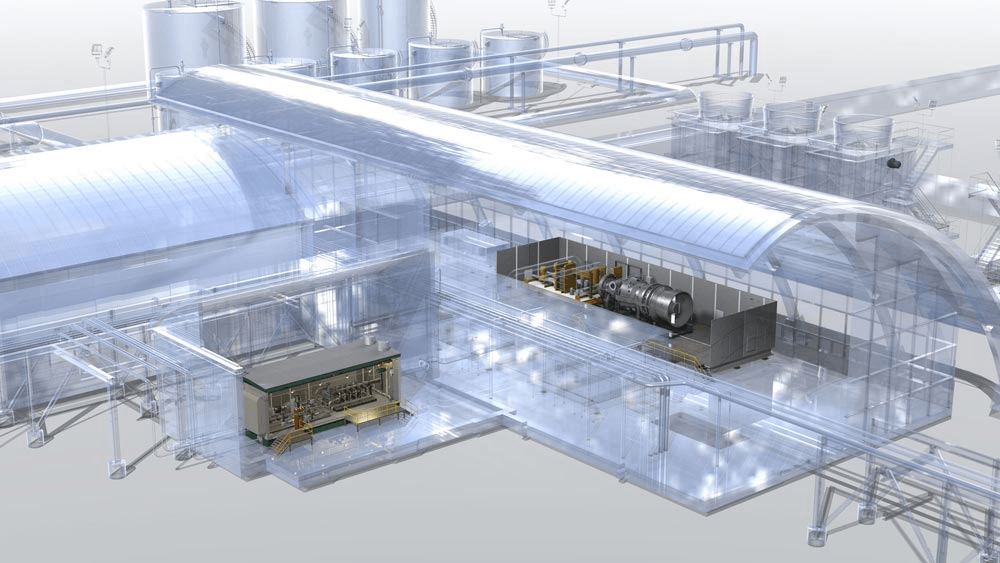

Revolutionary Oxy-Fuel Tech: Near-Zero Emissions for Reliable Power

Clean Energy Systems has developed reliable oxy-fuel technology that can produce near-zero emission electricity in a dispatchable manner. Clean and firm power is key to support customers with large baseload demand, such as AI data centers, as well as to provide grid-firming generation as increasing amounts of variable solar and wind electricity are brought online. CES’ oxy-fuel combustion technology provides almost 100% carbon capture, which is a key advantage compared to conventional post-combustion capture that struggles to cost-effectively reach capture rates of 90%+.

To Meet Increasing Demand

As global regulatory and corporate initiatives increasingly implement stronger greenhouse gas (GHG) reduction goals and more stringent NOx requirements, there is an increasing need for clean and firm power. Natural gas with carbon capture and sequestration (CCS), sometimes referred to as "blue electricity," has the potential to scale rapidly and leverage abundant, low-cost domestic natural gas feedstock. While geothermal and nuclear have a key role to play, natural gas with CCS has fewer geographic or resource constraints and offers a path to the lowest cost clean and firm electricity at large scales.

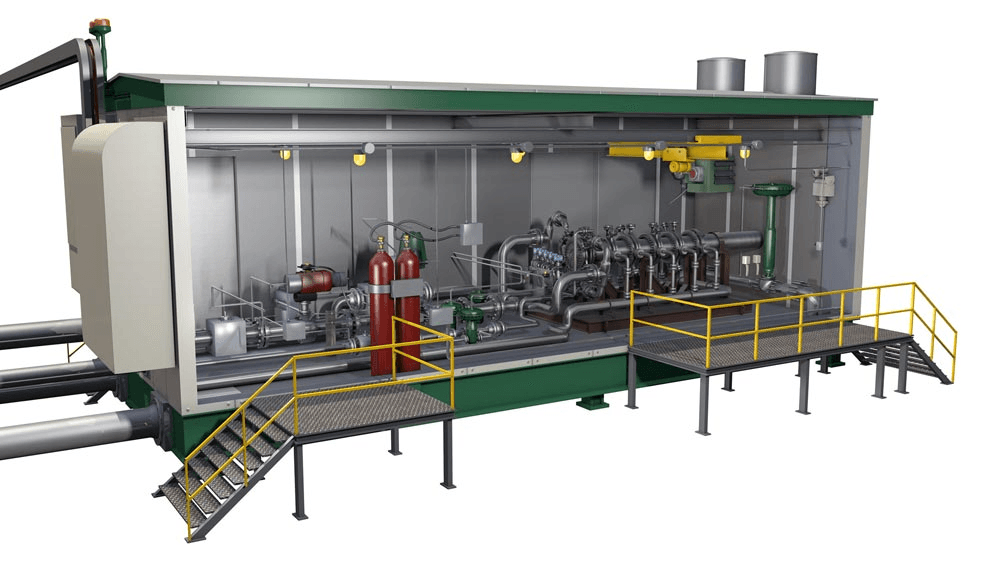

Modular and Scalable Solutions

CES is commercializing a 70 MW power module, which pairs proprietary oxy-fuel burner technology with standard steam turbine technology. To deliver larger projects, multiple CES modules can be deployed and paired with larger turbines to achieve greater economy-of-scale. Future generations of CES technology are in advanced stages of development and will enable higher net cycle efficiencies to unlock higher power outputs from a single module.

Load Following and Fast Response

Similar to conventional natural gas power turbines, CES power plants have operational flexibility to ramp-up and down to meet the needs of large co-located customers and/or to react to electricity market price signals. CES power plants also have added operational flexibility to “peak” and temporarily produce additional power for periods of hours or even a few days, by using stored liquid oxygen and operating the air separation unit (ASU) at reduced loads.

If deployed for emergency start-up or peaking power applications, CES oxy-combustion plants require less time to start-up compared to conventional gas peakers, which typically take 10-30+ minutes to start-up and reach the required operating temperatures for expensive NOx catalysts.