"Deploying technology that makes 'Power without Pollution' a reality."

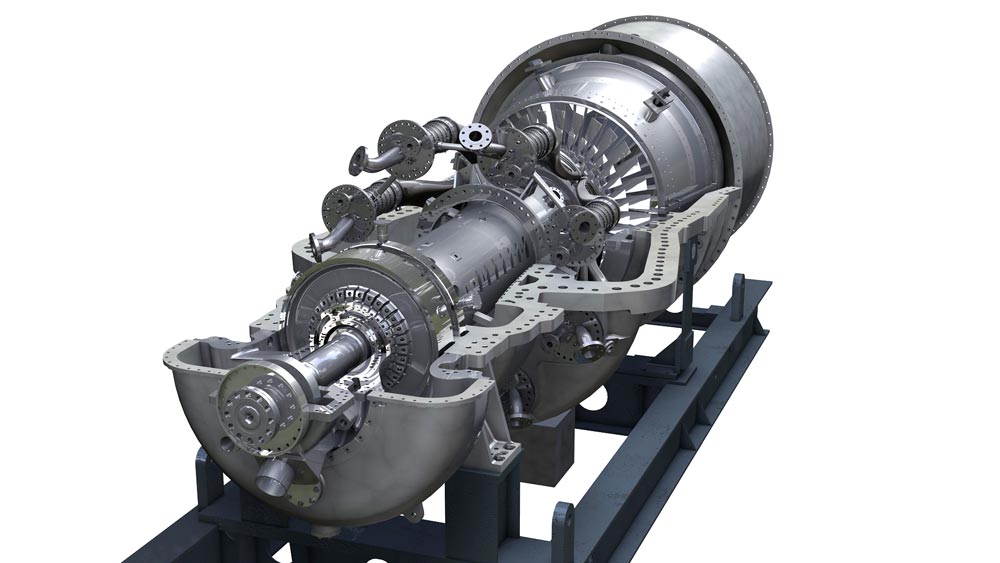

DIRECT STEAM GAS GENERATORS

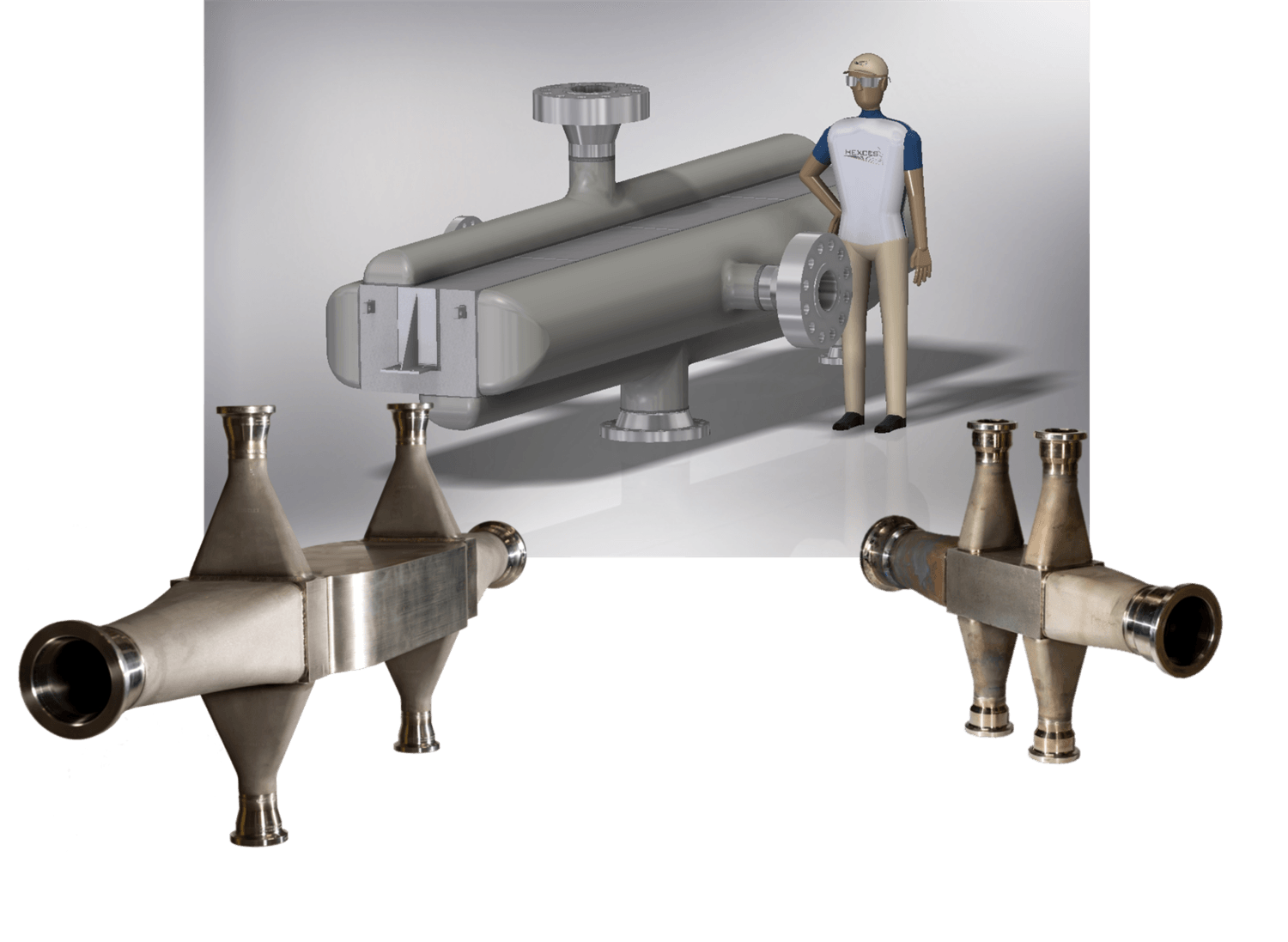

CES’ direct steam gas generators, or gas generators (GGs) for short, provide a safe, reliable method for blended steam and CO2 production.

Also known as direct contact steam generators, CES GGs consists of three main parts: a burner, attemperator, and associated feed and controls systems. The GG burner utilizes platelet technology to intimately mix gaseous fuel with oxygen in the presence of water for stable, efficient combustion. Multiple attemperation chambers inject water to cool the resulting superheated, high-pressure steam and CO2, producing additional steam and controlling combustion chemistry. The attemperation section is extremely compact, spanning only about 6.5 feet, but is adaptable for different applications. Associated water, oxidizer, and fuel feeder systems are designed for the specific fuel qualities targeted in your project.

You can learn more about CES' direct steam generation technology and some typical process configurations by downloading our brochure.

4" Direct Steam Gas Generator

The GG400 uses a 4 inch internal diameter system design and is rated for 20 MWt when running on pipeline quality natural gas at typical pressures.

Applications

- Steam Assisted Gravity Drainage (SAGD)

- Food-grade CO2 generation

- Desalinization plants

Typical Dimensions:

L40' x W11' x H11' in operational enclosure

Features

- Fully sufficient minimum footprint module

- Allen Bradley control system

- Easy access maintenance system for full module or component replacement

- 24-hr full overhaul maintenance capability

Specifications

| Power Output | 20MWt |

|---|---|

| CO2 Output | up to 15,000 mscfd (based on NG and 400 psi inlet) |

| Drive Gas Output | up to 50,000 lbs/hr |

| Inlet Pressure | up to 1,500 psi (customizable up to 5,000 psi) |

| Pressure Drop | 15% |

| Exhaust Temp | saturation up to 1,760 °C (3,200 °F) |

12" Direct Steam Gas Generator

The GG1200 is a scaled version of the GG400 using a 12 inch internal diameter system rated for 200 MWt when running on pipeline quality natural gas at typical pressures.

Applications

Typical Dimensions:

L40' x W11' x H11' in operational enclosure

Features

- Fully sufficient minimum footprint module

- Allen Bradley control system

- Easy access maintenance system for full module or component replacement

- 24-hr full overhaul maintenance capability

Specifications

| Power Output | 200MWt |

|---|---|

| CO2 Output | up to 15,000 mscfd (based on NG and 400 psi inlet) |

| Drive Gas Output | up to 500,000 lbs/hr |

| Inlet Pressure | up to 900 psi (customizable up to 5,000 psi) |

| Pressure Drop | 15% |

| Exhaust Temp | saturation up to 1,760 °C (3,200 °F) |

Safe, reliable power that doesn't compromise the environment: It's been our mission since the beginning.

All Rights Reserved | Clean Energy Systems | Website Design by: MyCali Designs