May 29, 2025

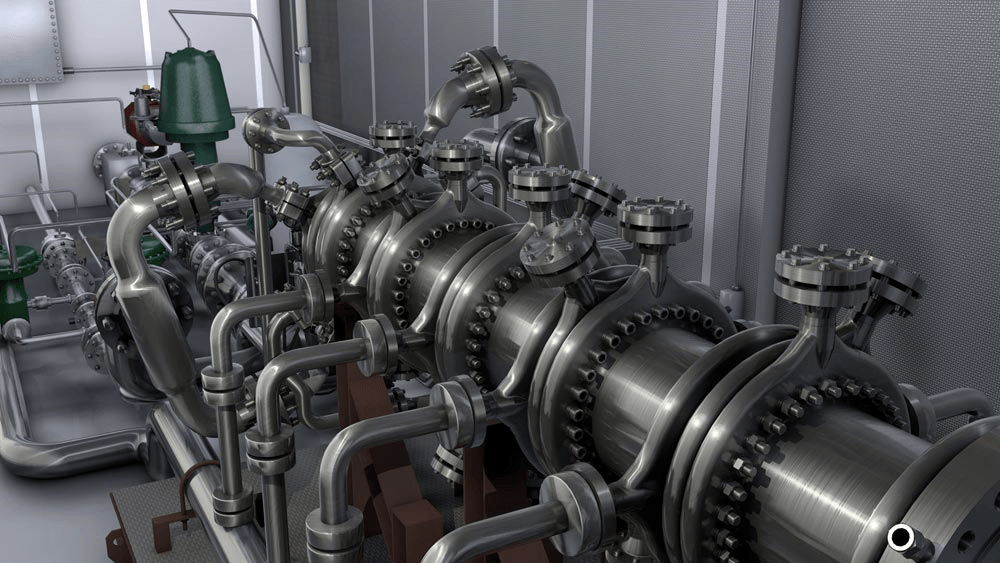

Rancho Cordova, CA – May 29, 2025 – Clean Energy Systems (CES), a pioneering force in carbon-free combustion technology and zero-emission power solutions, is thrilled to announce the appointment of Mark McGough as its new Chief Executive Officer. This strategic leadership addition marks a significant inflection point for CES as it scales its breakthrough technology to meet surging global demand for clean energy. With more than 30 years of experience building high-growth energy technology companies, McGough brings an extraordinary track record of innovation, international commercialization, and shareholder value creation. His leadership is expected to catalyze CES’s mission to redefine how the world powers industry—without carbon emissions. “With global demand for clean, carbon-free energy solutions reaching an all-time high, his arrival is perfectly timed,” said Jonathan Goldberg, Board Director at Clean Energy Systems. “Mark’s track record of scaling innovative technologies and accelerating commercial deployment makes him the ideal leader to guide CES through this critical phase of growth and market opportunity.” CES is on a mission to revolutionize energy production through its patented oxy-fuel combustion systems—derived from proven rocket engine principles—to eliminate carbon emissions from industrial processes and power generation. With rising global pressure for decarbonization, CES’s technology is at the heart of a new industrial energy paradigm. “I’m honored to take the helm at such a dynamic and pivotal time,” said McGough. “CES under my predecessor has built a world-class platform with game-changing technology. My focus will be on accelerating commercialization, deepening global partnerships, and scaling our footprint to meet the urgent global demand for zero-emission solutions.” Clean Energy Systems is uniquely positioned to lead the clean industrial revolution, turning carbon-free combustion into a practical, profitable reality for energy-intensive industries worldwide.